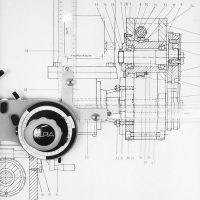

Can Man is a family-owned and -managed, medium-sized company that manufactures and sells equipment for the production of welded cans, pails and drums as well as for the HVAC – industry.

The product range includes solutions for blank cutting, feeding (transport), welding and curing, as well as upgrades and spare parts for canbody welders of other manufacturers.

Our products are characterized by highest flexibility for fastest format changes, simplicity for easiest operation and quality for most reliable production.

Ruedi Umbricht

General Manager

Johnny Umbricht

Production Manager

Marianne Umbricht

Sales Manager

by Ruedi Umbricht. Starting to upgrade welding bodymakers with simplified static frequency inverters and stronger wire profiling units for the WIMA – welding.

As business was picking up, Johnny, Ruedi‘s brother, joined the company.

Due to the total absence of competition in the welding machine market, first ideas to design a fully automatic Can Man welder appeared.

CM18 with 4 tools and for a production speed of max. 40 can per minute was designed, built and put into production in Denmark.

CM16 for 80 cans per minute, at the end of 1996, followed by a version for up to 180 cpm.

Marianne, the sister of Ruedi and Johnny, joined the company to support sales and administration.

Rejecting an approach from the key persons of Sabatec to take over their company, but inspiring them to become equal partners and re-launch their business focussing on spare parts.

Moving from a 200 m2 workshop in Aarau to the 1500 m2 production site in Hallwil.

CM15 (todays X5) a high speed welder for large formats entered the market.

CM21 the worlds first semiautomatic welder for WIMA-welds without a calibration crown.

Another premier: The Pacemaker™, a new static frequency inverter, fully digital controlled and on a platform, that allows constant upgrades through software.

Our low to medium speed welder got upgraded to be able to run up to 300 cans per minute.

The sole proprietorship is converted into a shareholder company.

In a „bombshell – like“ Introduction at the Meatpack2005 2 new welders have been introduced: A revolutionary high speed welder with several new features and a low speed welder replacing the aged CM18 – concept. Both welders came in today’s well known Can Man – design.

Can Man initiates a network of the finest canmaking machinery suppliers providing turnkey 3-piece canproduction lines.

Production peak with 35 welders delivered within one year!

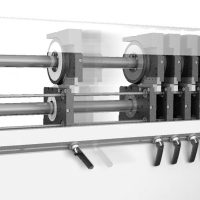

Filling the gap for a Swiss made, hyper-precise double slitter, optimized to handle thinnest sheets and providing best possible flexibility at highest speed

Down the canbody production line, some innovation was required, so Can Man introduced the breakthrough in canbody induction curing unit with energy savings of 80% compared to conventional curing systems.

For the first time Can Man suffers a lack of incoming orders after years of fantastic growth and is forced to re-organize the company with loosing 1/4 of the staff.

Medium-speed weldcenter with protection cover against noise and environmental influences.

Switching from PLC to a new generation of machine controls, based on powerful industrial PC’s.

Extending production depth and shortening production time by expanding the company’s own mechanical production in a separate near by facility.

The latest addition to the top slitter are the monobloc cutting-heads for superfast height change.

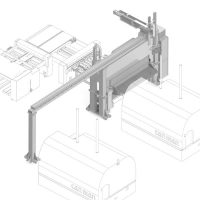

Until introduction of the X4 drum welder, flexibility was unknown to such machines. Now, this highly automated drum welder allows a 10 minute – changeover within the entire format range.

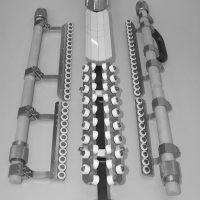

Versatile blank feeding system for all kind of layout – desires and even for double line feeding is available.

It took 5 years to reach the turnover of the years before the crises, but now with the highest profitability ever in the Can Man history.

A buffer that serves up to 60 minutes blank-stacks while the slitter is down and therefore shortens a complete format change of a Can Man line to less than 1 hour.

Radical optimized and largely simplified medium to high speed welder X7, targeted to be the perfect replacement for the hundreds of aging welders worldwide.

Can Man manufactures and sells equipment for the production of welded cans, pails and drums.

The product range includes solutions for blank cutting, feeding (transport), welding and curing, as well as upgrades and spare parts for canbody welders of other manufacturers.

Our products are characterized by highest flexibility for fastest format changes, simplicity for easiest operation and quality for most reliable production.

1

Manufacturing Location: Hallwil Switzerland

22

Distribution Partners

3

Technical Backup Centers

> 400

Welders running

98%

Export Quota (Worldwide)