You can perform a complete format change in just 30 minutes – the world record for medium- and high-speed welders!

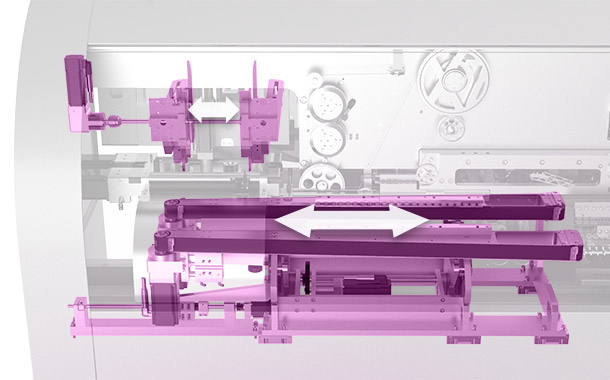

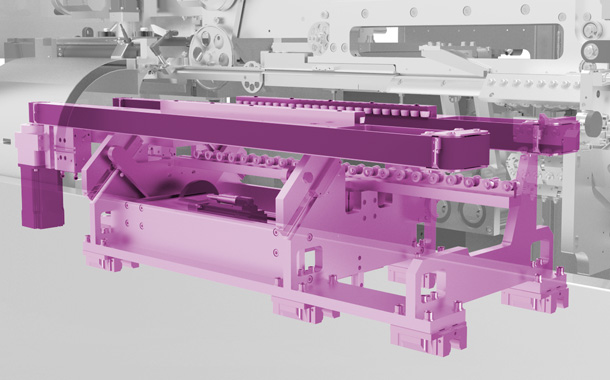

Two high performance, linear servo drives are used for the downstacking and insertion of the blank into the rollformer. The blank thickness measurement is done right after downstacking and before insertion of the blank into the rollformer.

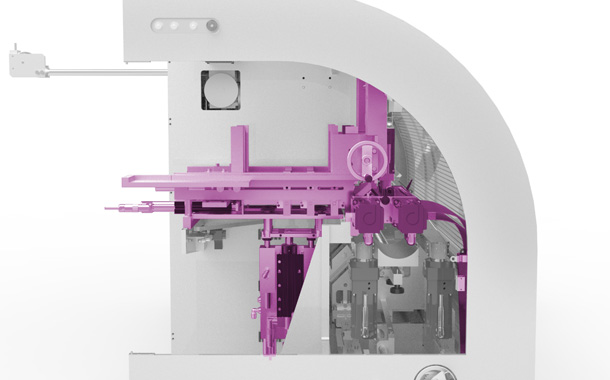

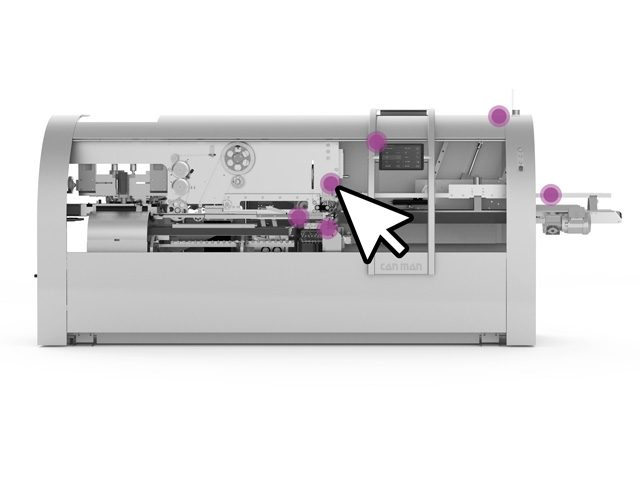

The synchronisation of tinplate entering the rollformer, the rounding process and the impact of the rounded blank at the catchrail is controlled by servo drives (patents pending). Servicing this unit is a “no brainer”. The SmartFORMER™ is available for max height 120 mm or max 320 mm, with or without scoring station and with or without triangle embossing, and can be easily exchanged due to its lightweight (32 kg).

The canbody transport also serves as a canbody pre-guidance and it automatically adapts to any canbody diameter you may select at the push of a button. This makes the change of format-dependent guide channel unnecessary.

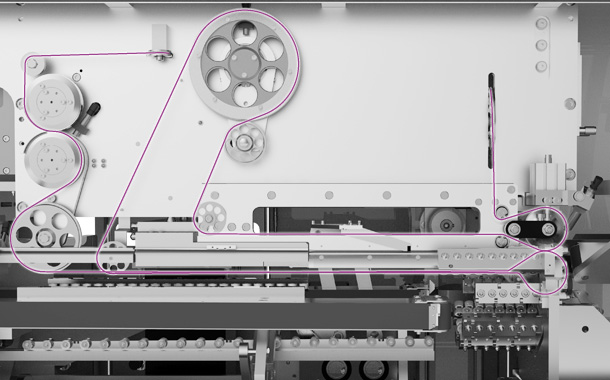

The wire cooling is essential on high speed welders. It assures best possible welding roll performance and increases the rolls lifetime considerable. As in all Can Man welders, the wire routing is among the most simple ones ever made. Compare it with any of your welders and you’ll see the difference.

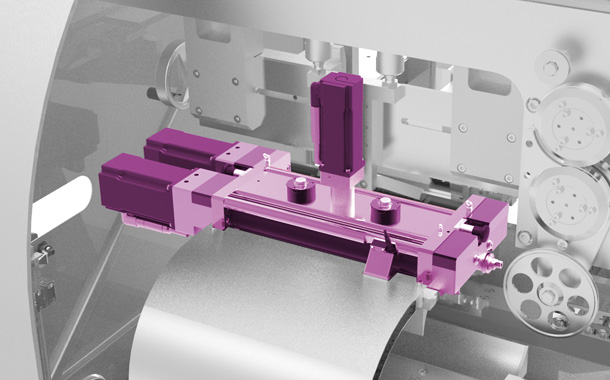

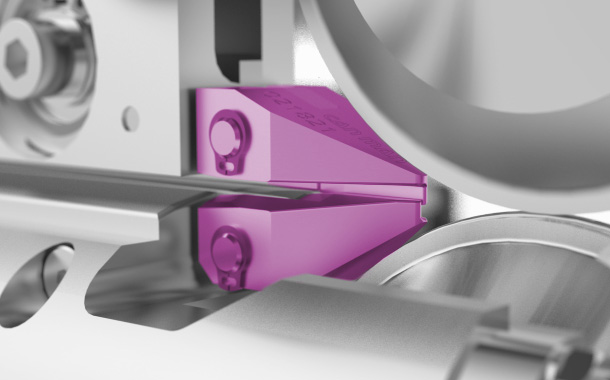

The split nosepiece has to be changed only partially if worn, and even ceramic made ones which are sensitive to tensions cannot break.

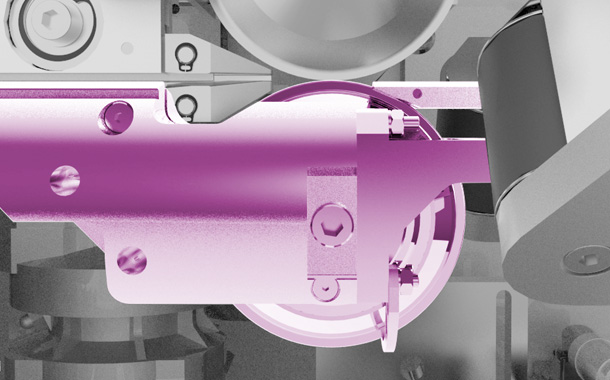

Optimized for the use with a “flying” powder arm: while the lower welding arm remains fixed in its position, the redressed welding roller is re-adjusted along its flat surface. It also increases the power transmission significantly.

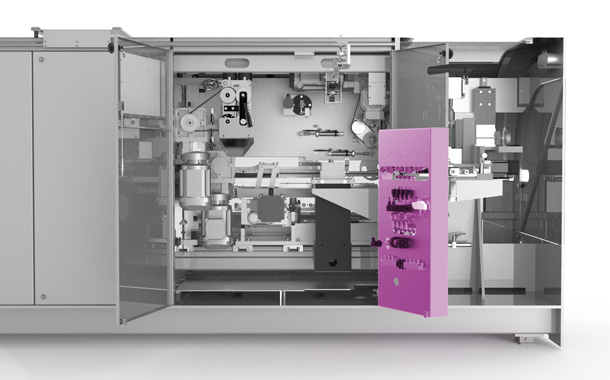

The entire water- and air supply unit can be swung out and ensures full access to all the vital parts of a welder and therefore eases the maintenance.

This Swiss made welder concept is the perfect solution for medium- and highspeed productions and on top of the precision, easy operation, fast changeover is the unbeaten price / performance rate. Compose your X7 WeldCENTER™ in the configurator and get your quote today!

| Diameter range | (45) 52 - 153 mm |

|---|---|

| Height range | 50 - 120 / 320 mm |

| Blank thickness | 0.12 - 0.28 mm |

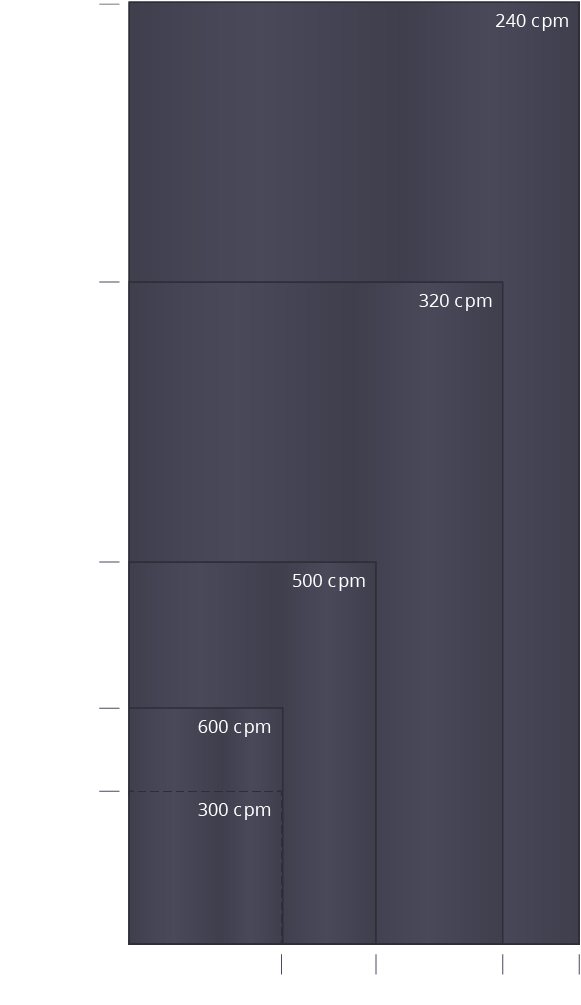

| Production output |

100 - 400 / 500 / 600 cpm Max. 1200 cpm (after parting) |

| Welding speed | 20 - 70 / 85 m/min |

| Wire diameter | min. 1.24 mm |

| Format change | 30 minutes |

| Height change | 5 minutes |

| Electrical mains | 3 x 400 VAC + Ground, 50/60 Hz |

| Fuse and power | 3 x 63 A, 35 kVA |

| Water Pressure | 5 bar (absolute) |

| Flow rate | min. 40 l/min |

| Cooling power | min. 2 x 12 kW |

| Air pressure & consumption | 6 bar, 72 m³/h |