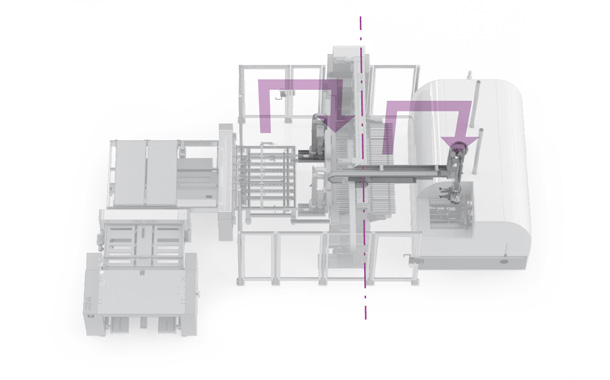

The PowerFEED™ S1 and S2 have two independent working units with separate safety zones (slitter to buffer and buffer to welder). While one part requires access, the other can continue. That means no unnecessary downtime, respectively an increased line efficiency. Be reminded that an unnecessary 10 minute downtime will drop your line efficiency by 2 % per shift (based on an 8 hour shift) or more than 15 % per hour.

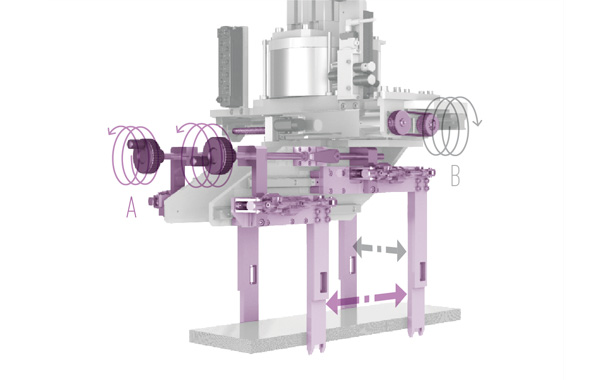

The PowerFEED™ is back in production while all other systems still struggle for 2 or more hours! The adjustment of the blank length is done within seconds by 2 manually adjustable spindles. The height-change is done fully automatically by means of a servomotor and requires only a touch on the SmartCONTROL™.

| Production output | 5,5 stacks per minute or 2 x 2 if feeding 2 welders |

|---|---|

| Blank stack handling | Max 15 kg |

| Blank thickness | 0.1 - 0.4 mm |

| Format change | 20 minutes |

| Height changeover | 15 minutes |

| Electrical mains | 3 x 400 VAC + Ground, 50 / 60 Hz |

| Fuse and power | 3 x 16 A, 5 kVA |

| Connection load | 5 kWh |