For the first time small orders for everything which can be called a drum can be done automatically and we’re sure that’s what many small and medium sized drum makers can’t do easy (or only with semiautomatic, labour-intensive welders).

The production range starts from ø 230 mm for small drums with material thickness of 0.4 mm and goes up to ø 575 mm for large drums with plate thickness of up to 1.5 mm. All kinds of materials may be produced, including stainless steel, completely scratchfree.

A set of 9 diabolo rolls minimizes the friction / risk of scratches at sensitive surfaces. A set is very attractively priced and colour coded, so that any diameter can be welded within the entire range of the machine. A format change becomes thanks to the quick release fasteners a plug & play job.

An entire format-, material- and speed-change can be performed in 10 minutes! 20 servo drives adjust the stored settings fully automatically. The clear user-interface makes setup, operation and control a joy. Acess is not only possible with the wireless operation panel but from any device, from anywhere.

Numerous sensors monitor and regulate the production process to ensure highest quality, lowest wear, top efficiency and minimize waste. The basic system of sensors at the downstacker, rollformer, welding and calibration rolls can be easily supplemented with Can Man’s advances Qualimaker™2 weld monitor.

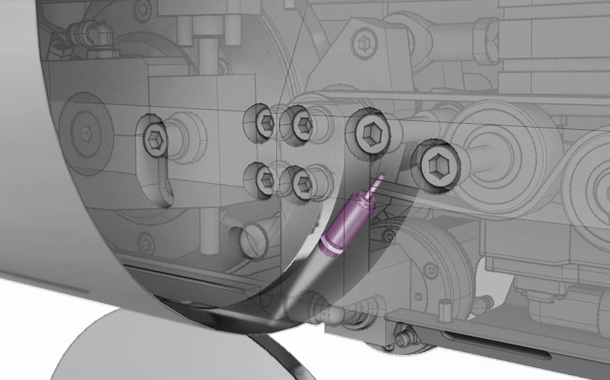

The entire calibration tool can be, automatically supported, moved forward. That allows before unseen accessibilities for setup and service. For example when it comes to exchange or redressing of the welding roll or replacement of the Z-bar.

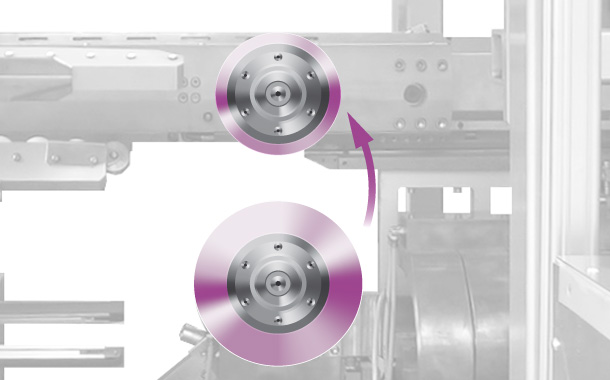

The synchronized drive of the inner and outer roller-head improves the weld quality of the welding results and reduces the wear of the welding rings. Of course are the welding rolls mercury free and the special design of the welding roll body allows an exchange of inner and outer ring for maximum utility.

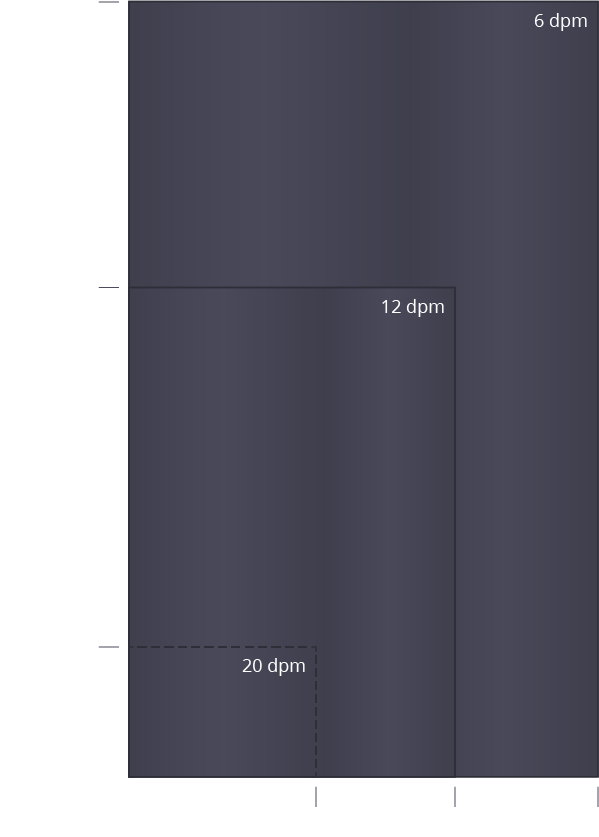

| Diameter range |

230 - 400 mm (smaller version) 350 - 575 mm (bigger version) |

|---|---|

| Height range | 160 - 950 mm |

| Material thickness | 0.4 - 1.5 mm |

| Weldable material | Stainless steel, blackplate, galvanized steel |

| Production output | up to 20 drums/min |

| Welding speed | 3 - 12 m/min |

| Format change | 10 minutes |

| Height change | 5 minutes |

| Electrical mains | 3 x 400 VAC + N + Ground, 50 / 60 Hz |

| Fuse | 3 x 80 A, 45 kVA |

| Water Pressure | 6 bar |

| Flow rate | 30 l/min |

| Cooling power | min. 15 kW |

| Air pressure & consumption | 6 bar, 20 m³/h |