Problem:

The push fingers to feed the stripes into the 2. operation do not work or do not always work properly and no error message appears.

Possible Causes & Resolutions:

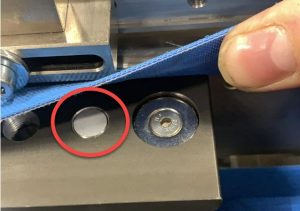

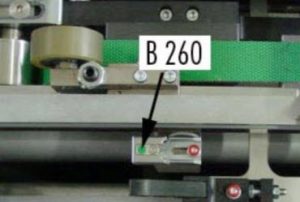

- The stripes must slide flat on the table at all times so that they are correctly detected by the sensors B260 and B261 that trigger the Linmot pusher. See the pictures below where the sensors B260 and B261 are located on the newer and the older slitter type.

- Clean the senors B260 and B261. Metallic dust can lead to malfunctions.

- Check the height of trigger sensors B260 and B261. If they are set too low they can not detect the stripes properly.

- Check the spring load of push fingers. If the spring load is set to high, the stripes can be lifted up if they pass the fingers and this can create detection issues for the trigger sensors B260 and B261. Adjust the spring tension so that the push fingers return reliably to the upper position but with as little pressure as possible.

- Gap between stripes is too low. The push fingers need time to return to the initial position. If the gap between the stripes is too small, the push fingers may not yet be ready to feed the next stripe. Check the value of stripe width on HMI. Is it set correctly?

- Defective trigger sensor or sensor cable B260 and B261.

- Defective linmot controller U26. Check linmot controller for error message. Contact CanMan.