Possible Causes & Resolutions:

- Check the blank cutting tolerances and quality (download form for cutting tolerances): If the cutting measures are out tolerance, blanks will create downstacking and double sheet errors.

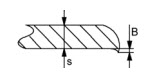

- Check the burrs on the blanks (Cutting burrs B max. 0.15 x sheet thickness s): If the burrs are too big, the blanks will create downstacking and double sheet errors.

- Check the general setting of the blank magazine acc. instruction manual. The separator notches should always be aligned with the suction cups.

- Check the separating air: If the separating air pressure is too high or tool low, the bottom blanks will not being separared correctly. Try with more or less separating air.

- Check the position of the separation air nozzles: The air shall always being directed towards the most fanned-out part of the sheet stack. The distance between the separation air nozzles and the sheet stack should be a maximum of 1mm.

- The top position of the suction cup should always be adjusted with the separation air turned on to prevent it from being set too high. Otherwise the separating air between the sheets is pressed out which will lead to double sheets.