Problem:

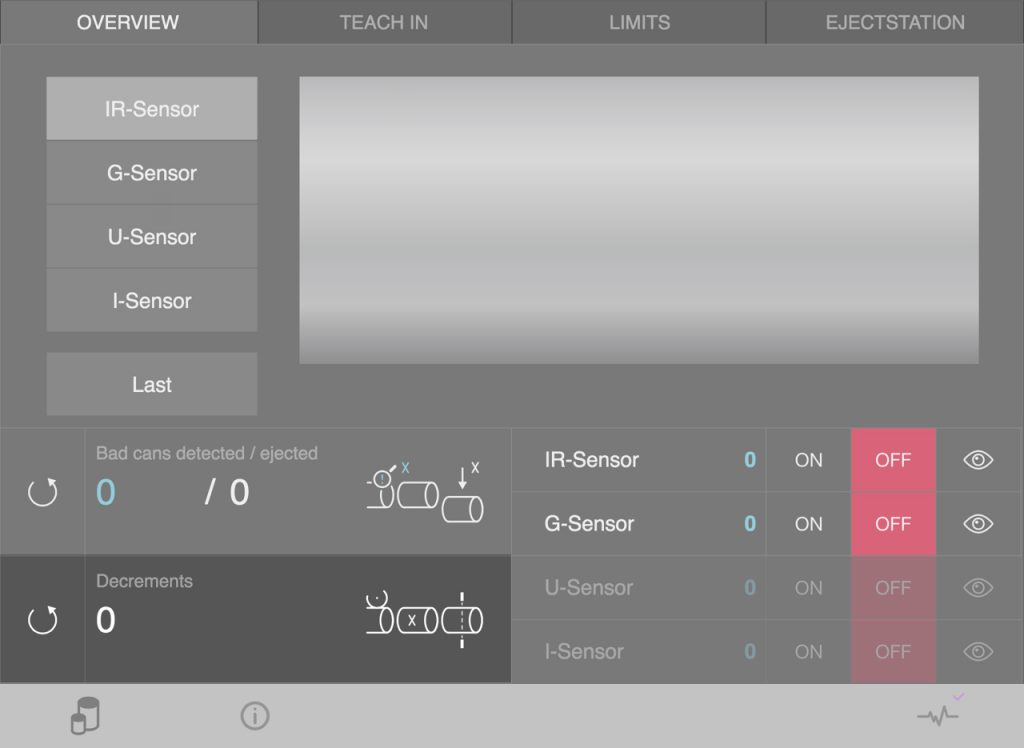

The decrement counter shows the number of cans between the welding station and first light barrier of the eject station. If the value is wrong, the ejection of cans is out of sync with the faulty products.

Resolution:

- The reason for a wrong decrement counter can be a reset during production.

Attention(!): Reset the decrement counter only if the production is stopped and no cans are between the welding station and eject station, NEVER during production! This is important to avoid that bad cans go to the downline.

Problem:

The decrement counter is not stable, which leads to continuously smaller values during full production.

Possible Causes & Resolutions:

- Tooling sensor signal is not stable. The tooling sensor might not detect all cans properly due to the distance between the cans and sensor.

➔ Please check the distance of the sensor to the can, it should be as close as possible without it touching the can.

- Cycle signal of machine is not stable.

➔ Check the cycle signal: If the machine signal comes from a sensor, check sensor settings or replace sensor.