The motherboard battery is a CR2032 lithium-metal cell. It is used to supply power to the clock integrated on the motherboard. If the battery is depleted or missing, the date and time are displayed incorrectly. Recommendation for replacement interval is 5 years.

For instructions on how to replace the battery use the download link below. You will also find the correct battery type there.

The motherboard battery is a CR2032 lithium-metal cell. It is used to supply power to the clock integrated on the motherboard. If the battery is depleted or missing, the date and time are displayed incorrectly. Recommendation for replacement interval is 5 years.

For instructions on how to replace the battery use the download link below. You will also find the correct battery type there.

All Beckhoff control units are equipped with a UPS to ensure the proper shutdown of the control IPC. However, this only works if the battery is in perfect condition to prevent data loss and ensure the flawless operation of the control system. The battery module for the UPS must be replaced every 5 years.

To order a new battery please contact spares.canman@soudronic.com.

For instructions on how to replace the battery use the download link below. You will also find the correct order number there.

All Beckhoff control units are equipped with a UPS to ensure the proper shutdown of the control IPC. However, this only works if the battery is in perfect condition to prevent data loss and ensure the flawless operation of the control system. The battery module for the UPS must be replaced every 5 years.

To order a new battery please contact spares.canman@soudronic.com.

For instructions on how to replace the battery use the download link below. You will also find the correct order number there.

Problem:

Circuit breaker Q5 trips when the machine is switched on or during production.

Possible Causes or Resolutions:

Problem:

All drives are starting correctly, but the vacuum and welding current are not active.

Possible Causes & Resolutions:

Problem:

Some Beckhoff i/o terminals are not active and status LEDs are off, control does not respond to commands.

Possible Causes & Resolutions:

Problem:

After main switch off and on again, HMI piece counter values and settings are lost or old recipes are loaded.

Possible Causes & Resolutions:

Problem:

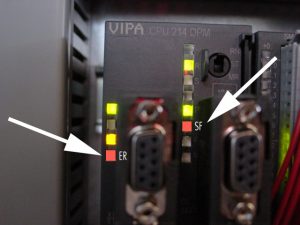

Machine stops and message „Pacemaker: Profibus communication error“ is displayed.

Possible Causes & Resolutions:

Problem:

The HMI cannot be started and the browser shows „NOT FOUND, The requested URL /en/default.htm was not found on this server“.

Possible Causes & Resolutions:

Not connected to Canman Wifi (only for wireless connected iPad’s): Check the wifi settings. Choose Canman wifi and try again.

IPC has not shut down correctly: In this case probably the HMI software can’t start up automatically by restarting the machine.

Check the IPC after you switched off the main switch: Normally it will continue to run for at least 30 seconds to shut down correctly. If LED’s of IPC goes off within a few second, the battery of the UPS – unit is dead and needs to be replaced. Contact Canman for online support to restart HMI.

Problem:

Possible Causes & Resolution:

Note: If you use a new iPad the icons for the machine type can be produced, when you tap on “Add to home screen“ button.

Problem:

Display shows „Could not activate iPad“

Possible causes & resolutions:

For connecting an alternative display / PC, please have a look at the separate FAQ.

Battery of IPC is empty when:

To Do:

Click here for the status LED’s of the Beckhoff PC and how to access the PC in case of a trouble shooting.

An overvoltage suppressor (or surge suppressor) is an appliance designed to protect electrical devices from voltage spikes. A surge suppressor attempts to regulate the voltage supplied to an electric device by either blocking or by shorting to ground voltages above a safe threshold.

These surge suppressors are built in to the latest Pacemaker models and machine controls (from 2009).

Check, if one or more modules of the surge suppressors are red/defect. Replace the red modules.

Attention!!!

Do not bridge the signalling contacts and run the machine with defective red modules because they no longer protect the system from voltage peaks!!!

If the modules are defective, check the main supply. Measure and check all voltages between the phases and all phases to earth before exchange the modules and restart the machine.

Possible cause:

1 or 2 (sender/receiver) sensors are fitted behind the first pair of rollers to recognize double sheets.

Sensor in the lower part.

A pneumatic cylinder operates the ejection flap.

Setting the double sheet sensor

B30

The evaluation unit for the double sheet sensor is located in either the control box (illustration) or in the immediate vicinity of the rollformer, on the feeder side.

To set the sheet thickness, take a single sheet and lay it on the support rails in front of the first roller pair. You can also open the roll- former and lay a sheet into the rear area by hand. Then close the rollformer again.

Now turn the single sheet back and forward in the first roller pair by hand with the help of the belt.

The two green LEDs „Power“ and „Relay“ should now be lit up on the evaluation unit.

If the red LED „Double sheet“ is lit up, you must carry out a correction.

Turn the left-hand screw „Thickness Adjust“ clockwise until the red LED goes out and the green LED „Relay“ lights up. Add 1-2 additional turns in the clockwise direction.

Now carry out the same procedure with two sheets (double sheet).

The red LED „Double sheet“ should now be lit up.

Possible Causes & Resolutions:

Possible cause:

NOTE: all timing settings are stored on the PLC and not on the memory card.

Find a complete error list together with the interpretation of the error codes

Download PDF here