How to bypass / remove a generator in case of failure on the PowerCURE V2 please check link below:

The motherboard battery is a CR2032 lithium-metal cell. It is used to supply power to the clock integrated on the motherboard. If the battery is depleted or missing, the date and time are displayed incorrectly. Recommendation for replacement interval is 5 years.

For instructions on how to replace the battery use the download link below. You will also find the correct battery type there.

The motherboard battery is a CR2032 lithium-metal cell. It is used to supply power to the clock integrated on the motherboard. If the battery is depleted or missing, the date and time are displayed incorrectly. Recommendation for replacement interval is 5 years.

For instructions on how to replace the battery use the download link below. You will also find the correct battery type there.

All Beckhoff control units are equipped with a UPS to ensure the proper shutdown of the control IPC. However, this only works if the battery is in perfect condition to prevent data loss and ensure the flawless operation of the control system. The battery module for the UPS must be replaced every 5 years.

To order a new battery please contact spares.canman@soudronic.com.

For instructions on how to replace the battery use the download link below. You will also find the correct order number there.

All Beckhoff control units are equipped with a UPS to ensure the proper shutdown of the control IPC. However, this only works if the battery is in perfect condition to prevent data loss and ensure the flawless operation of the control system. The battery module for the UPS must be replaced every 5 years.

To order a new battery please contact spares.canman@soudronic.com.

For instructions on how to replace the battery use the download link below. You will also find the correct order number there.

Problem:

Circuit breaker Q5 trips when the machine is switched on or during production.

Possible Causes or Resolutions:

Reason for error message:

Possible causes:

Problem:

Machine stops and message „Pacemaker: Profibus communication error“ is displayed.

Possible Causes & Resolutions:

Problem:

The HMI cannot be started and the browser shows „NOT FOUND, The requested URL /en/default.htm was not found on this server“.

Possible Causes & Resolutions:

Not connected to Canman Wifi (only for wireless connected iPad’s): Check the wifi settings. Choose Canman wifi and try again.

IPC has not shut down correctly: In this case probably the HMI software can’t start up automatically by restarting the machine.

Check the IPC after you switched off the main switch: Normally it will continue to run for at least 30 seconds to shut down correctly. If LED’s of IPC goes off within a few second, the battery of the UPS – unit is dead and needs to be replaced. Contact Canman for online support to restart HMI.

Problem:

Graph remains grey and shows no curves at all.

Possible Causes & Resolutions:

Avoid very fast switching between pages. This causes overloading of the browser.

Close alle open browser connection (HMI app) and wait for >2 min.

Now you should be able to open the HMI without error message.

Close HMI app on iPads with home button:

Close HMI app on newer iPads without home button:

Note: If you use a new iPad the icons for the machine type can be produced, when you tap on “Add to home screen“ button.

Problem:

Display shows „Could not activate iPad“

Possible causes & resolutions:

For connecting an alternative display / PC, please have a look at the separate FAQ.

Error message: Setup data corrupt / User data corrupt

Resolution:

How To:

Important things to know:

1. Problem:

The graph is not showing any values / no picture at all.

Possible Causes & Resolutions:

2. Problem:

The graph of the G-Sensor does not show a steady graph but shows greater fluctuations (= can gap).

Possible Causes & Resolutions:

Problem:

iPad does not connect to the machine. Screen remains gray and shows no values.

Possible Causes & Resolutions:

Battery of IPC is empty when:

To Do:

Reason for error message:

Possible causes:

For a Pacemaker-repair we calculate / estimate a “cycle-time” of 2 weeks, including final testing and packing. If a faster service is required, extra charges occur. In case the number of incoming repair jobs is unusual high, it might take more than 2 weeks.

Problem:

The decrement counter shows the number of cans between the welding station and first light barrier of the eject station. If the value is wrong, the ejection of cans is out of sync with the faulty products.

Resolution:

Problem:

The decrement counter is not stable, which leads to continuously smaller values during full production.

Possible Causes & Resolutions:

NOTE: Make sure that the wire is not touching anywhere. Only a perfectly set and maintained canbody welder, can assure perfect welding! A weld monitor is a pure “measuring instrument”.

Check this specific wire crossing (red arrow). The wire might touch each other here!

Check the connection from the voltage pickup to the Qualimaker board.

Possible cause:

Corrective measure:

Possible cause:

Corrective:

Cause:

The actual value of the weld power limiter increases with the heating of the machine.

Corretive:

Readjust the weld power limiter, to a higher value. Observe the “Max” value from a “cold “ start to a “warm up” machine during production. See also note below.

Download PDF here

Problem:

The display shows the set current value, but the duty cycle is very low or 0%!

Possible cause:

DO NOT ATTEMPT TO SWITCH “ON” THE CURRENT ANYMORE!

Further attempts to switch on the current, can destroy or damage the semiconductors (IGBT) in the Pacemaker!

An overvoltage suppressor (or surge suppressor) is an appliance designed to protect electrical devices from voltage spikes. A surge suppressor attempts to regulate the voltage supplied to an electric device by either blocking or by shorting to ground voltages above a safe threshold.

These surge suppressors are built in to the latest Pacemaker models and machine controls (from 2009).

Check, if one or more modules of the surge suppressors are red/defect. Replace the red modules.

Attention!!!

Do not bridge the signalling contacts and run the machine with defective red modules because they no longer protect the system from voltage peaks!!!

If the modules are defective, check the main supply. Measure and check all voltages between the phases and all phases to earth before exchange the modules and restart the machine.

Important requirements:

Possible problems, if the overlap function does not work!

Possible cause:

The Pacemaker™ static welding inverter has a RAM battery for data retention and clock-buffering at power interruption/disconnection. The battery has a limited life span (about 5 years) that decreases especially without power supply (controller off). To prevent loss of data, the battery must be replaced early enough > ONLY BY AUTHORIZED AND SKILLED PERSONNEL!

To order a new battery please contact spares.canman@soudronic.com.

For instructions on how to replace the battery use the download link below. You will also find the correct order number there.

How to change the battery on a Pacemaker™ with integrated Qualimaker V1 electronic board:

Possible Cause:

Possible cause:

Using a handpanel:

When you start up your Pacemaker, the software version will be displayed during the boot process.

Alternatively the information will we displayed, when you press the key “down” several times until you get to “Info Version”: e.g. 5.27

Using a CM16 welder you will also find the info by pressing the key “down”, since the display is the same as the handpanel of a PM.

Using a X1 welder:

Tip on the *eye” icon and the Pacemaker software version is displayed on the bottom line.

Using X8 welder:

Tip on the “eye” icon and then on a second “eye” icon to get to software version info on the bottom line – check also your manual book 1 – chapter 4.6. how to find the info.

Possible cause:

Download PDF english

Download PDF chinese

Problem:

Possible cause(s):

NOTE: The reason for the low current is due to an open circuit. The wire might be also hot in this case. If you have in general a high power percentage you might reduce the frequency.

Scroll down in the display menu until you reach the temperature display. Observe, if after crossing the switching threshold, the temperature doesn’t change, that the solenoid valve is blocked (when the 2nd thresholds are reached the message “over- or undertemperature” will be displayed).

NOTE: The error message “Ths too low (Ths = Temperature Heatsink)” might be an indication for a contaminated valve.

Possible cause:

The Pacemaker has the following options to connect the output of the weld power limiter to other systems/controls (i.e. can rejection control):

Possible cause:

If the voltage value drops below 350 V the error message “Phase voltage error” shows up.

Check the main supply: L1 / L2 / L3.

Check also the input directly inside the PM.

QM board defect?

A reason for a voltage error could also be a defect on the QM board, which receives it’s supply from the elec. board of the PM.

To verify a defect you can remove the supply cable. The voltage value should go up around 20V (e.g. 375V to 395V), which is normal. If the increase much bigger than 20V the QM board has a defect and need to be replaced.

The voltage value on the touch screen is much lower than on the main terminal!

As a matter of fact, this electrical balancing of the two values has been done by CANMAN prior to the delivery. If there is a discrepancy you can adjust it.

You have to lose the small electronic board of Qualimaker (if applicable). This board is supplied by the big electronic board of PM. If you remove this supply cable, the voltage value goes up around 20V (e.g. 365V to 385V), which is normal.

Now measure the input of terminals, for example 385V. Turn the small blue potentiometer (picture). Control the value on touch screen. Must be around 20V more than the measured value, if you have a QM board. If you have adjusted it, connect the supply of QM and now you have the correct value on touch screen.

NOTE:

Starting with the version of the V4 mainboard, the board has two potentiometers. You need to adjust the “UMains” potentiometer in this case.

FAQ – Trouble Shooting

Check

– Check the cooling-water-inlet.

– Check the “Ths” and “Tamb” on the display.

– Check the small fans of the Pacemaker

NOTE:

The error “Ths too low” means temperature heat sink (copperplate) too low. If the copper plate is too cold. It can damage the unit, if some condensation water flows to the electronic power parts.

Check if the valve closes correctly and clean the valve.

NOTE:

If you reassemble the valve, make sure you do it the right way (see picture)

Check the correct water flow direction.

Download PDF here

NOTE: The pictures showing a regular Pacemaker and not a Pacemaker HF as used in the PowerCure, but the issue is the same!

Check the fuse on the bottom side, near the mains electrical (only PM 400/500 – PM Micro has no fuse!)

Check also the cable on this holder, it might have bad or oxidised contact!

USE 2A T (slow) FUSE

DO NOT USE LARGER OR FAST TYPE OF FUSE!

Check, if one or more modules of the surge suppressors are red/defect. Replace the red modules.

NOTE:

These surge suppressors are only built in to the latest PM models (from 2009).

ATTENTION:

Do not bridge the signalling contacts and run the machine with defective red modules because they no longer protect the system from voltage peaks!!!

If the modules are defective, check the main supply. Measure and check all voltages between the phases and all phases to earth before exchange the modules and restart the machine.

Make sure that you do all the actions with the necessary care and that all manipulations and measures are done by a certified electrician and with a well insulated multimeter! However do not manipulate inside the unit before the front panel display shows a low U batt (<24V)-(condensator battery voltage)!

With main switch on, switch on the inverter and monitor the charging of the battery voltage (Ubatt).

If the charging process starts normally and the battery voltage (Ubatt) constantly increases above 360V, then stops and pre charge error appears, it may be that the limit for activating the main contactor is not reached. The reason can be a slightly lower 3-phase main supply. If you have measured all phases and they are stable only slightly lower, open a Canman support ticket to get information on how to adjust the limit for activating the main contactor.

If battery voltage does not at all increase, you may check the function of the “small precharge relay” and its output on the main board.

There is an LED (LD25) on that output showing the state of this output. If the precharge relay doesn’t react you may check the wiring.

If the battery voltage increases, but the “precharge time out” appears while the voltage is still increasing, it could be that.

a) a phase is missing or has an “under voltage”, therefore you should check the voltage of all three phases (also to ground!)

b) it could be that the rectifier (1) or even worse a condensator or an IGBT (2) is malfunctioning.

Measure the actual battery voltage and compare it to the display (Ubatt). (ATTENTION: Switch off the unit and wait ’til the battery voltage is low, before you remove the front cover!). The voltage could be beyond 550 Volt DC, so please use a voltmeter, which has the necessary range. The terminals are on the left top (usually red and blue coloured).

If the voltage shown on the display does not correspond to the measured voltage, it can be adjusted with the potentiometer.

During loading, check the LED on the power board, which connects to the condensers. Are they glowing up at the same time? After loading are LED’s still on?

If not one more condensers might bad or defect!

Possible cause, the signal “reduce current” is always active. With reduction switch on there is no measuring, that means “Ctol” and “Power Limiter”are not active.

Check the signal “reduce current”. Maybe the electronic card of the machine is defective.

Questions:

Do you have instructions on how to upgrade our current Pacemaker software? Yes.

Change of the processor board

The software for the Pacemaker is memorized on a small processor board. For an update with new software you need to change this board.

IMPORTANT:

Before you start to change the board write down all values/parameters (e.g. main current, frequency etc.) for each can you have saved in pacemaker memory.

This not necessary for the CMX1 and X8 welder, because the parameters are safed in the panel.

Switch of main switch of pacemaker / machine.

WARNING:

Wait 5 minutes before you remove the cover. Capacitors with high voltage inside!

Remove the processor board carefully by hand. Do not use any tools for that.

Install the new processor board.

Be careful about the board position and especially the position of the connectors.

NOTE:

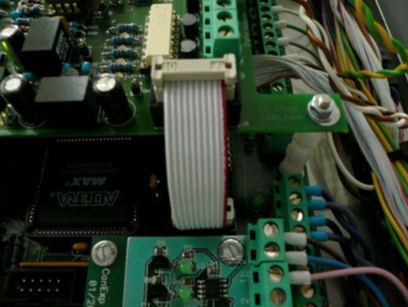

Depending on your current Pacemaker version you have to change the MAX IC as well.

The MAX IC controls all outputs and IGBT`s and works also with a software.

NOTE:

To remove the IC, use the delivered special tool. Never use a screwdriver or another tool. You will destroy the socket!

Check the main supply

R-380VAC (L1), S-380VAC (L2), T-380VAC (L3).

If you have connect the control panel and you can see only strange signs in the display, the connecting speed can be wrong. The Pacemaker control panel can run in two modes.

Control panel standard is 19200 baud (Used for connecting between control panel and PLC )

9600 baud

9600 baud (Used only for connecting between PLC and Pacemaker)

19200 baud

Control panel standard is 19200 baud (Used for connecting between control panel and PLC )

9600 baud

9600 baud (Used only for connecting between PLC and Pacemaker)

Possible Cause (CM16 / S, X8):

Adjustment of the light barrier distance to eject cylinder might be wrong.

Wrong adjustment of the transport belt speed.

NOTE:

The ejected can should whether touch the can before nor the following.

Eject pulse cylinder has to fit to production speed:

Recommendation: 150-200msfor<100cpm 100-150msfor100-200cpm

80-100msfor200-400cpm

Place a canbody between the second light barrier and check the LED „LD3“ on the eject print (inside the Pacemaker).

Must be „ON“.

The autoreset needs to be “OFF”. Therefore the can memory will not be reset automatically.

Check, if your hardware parameters are set correctly, according to one of the three layouts.

=> See layouts below!

Possible Cause (Pacemaker):

Cause 1:

The setting of t1 and t2 is wrong. If the timing is wrong the PM cannot execute the signal, which is necessary to memorize the canbodies in the reject unit and to start the record of the graph.

Setting of t1 and t2:

t1 defines the starting point for the reduced current time window. ![]()

t2 is the time, where the reduced current windows ends. t2–t1= thus is the timespan for the reduced current, therefore t2 > t1! ![]()

NOTE:

The value of t2 and t1 needs to be smaller as the cycle of one single can.

For example:

A production of 300/min. corresponds to a cycle time of 200 ms/can. Production of 600/min. corresponds to 100ms/can.

NOTE:

For a more detailed explanation of timing t1 and t2, consult your manual book 2, chapter 5.6.5. “Setting of Parameter t1 & t2 for reduced Current and Overlap Check“.

Cause 2:

Check the inductive proximity switch B64 at the final pusher unit for function, operating distance and defect.

B64

Final pusher (Synchrostar II): Sensor B64.

Description:

Inductive proximity sensor for embeddable mounting.

Polarity: PNP

Output: NO. or NC.

Operating distance: 2mm